| Sign In | Join Free | My chinacsw.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacsw.com |

|

Brand Name : Sussman

Model Number : RF-DL

Certification : CE, ISO, SGS

Place of Origin : Wuxi, Jiangsu Province, China

MOQ : 1set

Price : negotiable

Payment Terms : L/C, T/T

Supply Ability : 10sets/month

Delivery Time : 60days after accepting the advanced payment

Packaging Details : Film and steel

Steel thickness : 0.3-0.8mm

Forming speed : 8-12m/min

Roller stations : 18stations

Roller material : 45# steel

Shaft diameter : 75mm

Main power : 7.5Kw

Voltage : 380V or as your requirement

Hydraulic pressure : 12Mpa

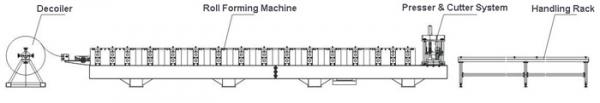

Roof And Wall Panel Double Layer Roll Forming Machine With 18 Groups Of Roller Stations

Technical Parameter

1. Suitable Plate Material: thickness 0.3-0.8mm, Galvanized steel S235JR

2. Working Speed: 8-12meters / min

3. Forming machine: 18 stations

4. Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

5. Material of Shaft: 45# Advanced Steel (Diameter: 76mm), thermal refining

6. Driven system: Chain Driven 1.2 inches 20A double chain with longer shafts

7. Main Power with reducer: 7.5KW

8. Cutting: Hydraulic Cutting Cr12mov

9. Material of Cutting Knife: Cr12Mov, Quench HRC58-62

10. Hydraulic Station Power: 5.5KW

11. The whole machine is controlled by industry computer-PLC.

12 PLC--Panasonic, Japan English and Chinese Language

13. Touch Screen--Panasonic Japan

14. Encoder--Omron, Japan

15. Electric parts--Schneider

16. Outline of main about 4000mm*1350mmm*1200mm

17. Weight : about 12 tons

Main Components

Serial No. | Commodity & Description | Quantity |

1 | 5T manual uncoiler | 1 set |

2 | Leveing guiding | 1 set |

3 | Servo feeding device | 1 set |

4 | Main roll forming machine | 1 set |

5 | Hydraulic station | 1 set |

6 | Cutting device | 1 set |

7 | Finished products tabel | 1 set |

8 | PLC control system | 1sets |

9 | Out tables | 1 sets |

| 10 | Spare parts | 1 sets |

Working Flow of Roll Forming Machine

Uncoiling—Feeding&Leveling--Roll forming—Cutting—Products collecting

Profile of product

Loading pictures

Our After-Sales Service Commitments

Sussman hereby solemnly promises: We implement the “three guarantees” service policy for any equipment sold by Sussman, provide free of charge installation guidelines, commissioning and maintenance of the equipment, training of the Buyer’s relevant Operators; and provide technical requirements for the installation and operation of the equipment, technical layout diagrams and other related information, provide a lifetime supply of maintenance and spare parts

The detailed measures are as follows:

1.Guidelines for installation and commissioning of equipment:

Based on the actual situation, to assist and guide the Buyer and Buyer’s technical personnel in the overall installation location, the installation of equipment, and provide Buyer with answers to their questions and related issues;

2.Provide training for operation and maintenance personnel:

Based on the Buyer’s request, Sussman will provide free of charge training of the operation and maintenance personnel;

a) The User (Buyer) can send their operation and maintenance personnel to our factory for learning and training;

b) When Sussman is doing the installation and test running of the equipment for the Buyer, the Buyer can send their personnel to participate.

3.If failure occurs in any of the machines during the “three guarantees” period(one year), then, upon the Buyer’s request, Sussman will eliminate the failure;

4. Sussman will inform all its Buyers about any upgrades and significant product improvements. Sussman will provide equipment modifications based on their costs. Sussman will provide Buyers with high-quality after-sales services in a careful and responsible attitude, provide very strong guarantee for the Buyer’s normal production.

We provide quick and satisfactory customer service, and promise to respond within 24 hours after receiving your complaints by phone or email

FAQ

1) Q: Are you manufacturer or trading company?

A: We are manufacturer and trading company .

2) Q: Do you provide installing and training overseas?

A: Overseas machine install and worker training services are optional.

3) Q: How is your after sales support?

A: We provide technical support on line as well as overseas services by skillful technicians.

4) Q: How does your factory do regarding quality control?

A: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment.

5) How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. Or,

2) We welcome your visit us and test machine by yourself in our factory.

6) Q: Do you sell only standard machines?

A: No. Most machines are made to order.

|

|

Roof And Wall Panel Double Layer Roll Forming Machine With 18 Groups Of Roller Stations Images |